-

Products

-

Solutions

-

Industry Solutions

-

Industry Solutions

-

-

Service Center

News

-

About Us

-

Investor

Join Us

Contact Us

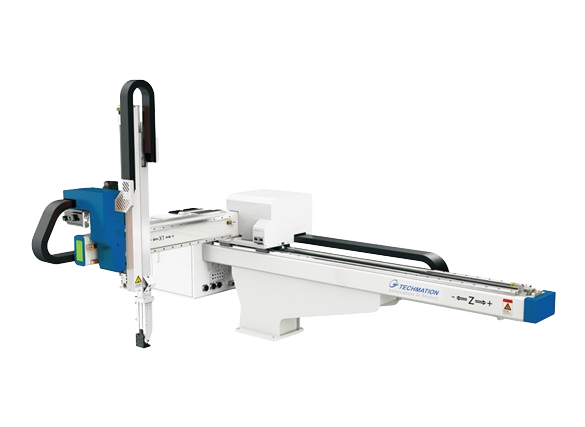

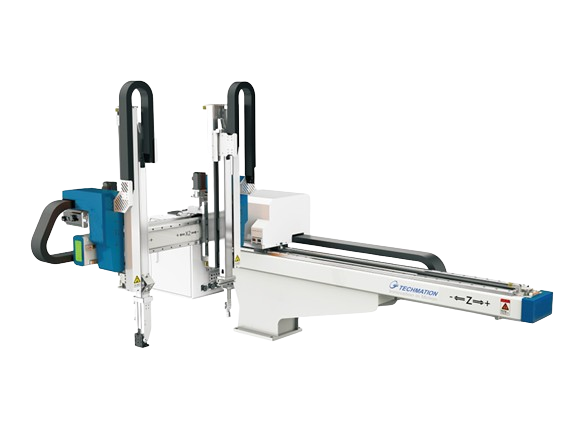

Manipulator

E-Series Fully Servo-Driven Manipulator

A manipulator is a robotic arm-like mechanism that is designed to manipulate or move materials, tools, and parts without direct human contact. Manipulators resemble some functions of the human upper limbs consist of a number of segments. They are used in industrial applications to effectively perform tasks like transporting products or production operations.

Owing to their progressive advancements, manipulators have found extensive applications in various sectors, including automotive manufacturing, consumer goods packaging, optical fabrication, and more. Instances of their use include the removal of finished products and nozzles from injection molding machines, automatic cutting or removing the excess glue port, spraying mold agent , in-mold inserts, in-mold labeling, out-of-mold shaping, assembly, stacking, and packaging. These applications have resulted in staff reductions, enhanced efficiency and quality, and improved safety for customers.