-

Products

-

Solutions

-

Industry Solutions

-

Industry Solutions

-

-

Service Center

News

-

About Us

-

Investor

Join Us

Contact Us

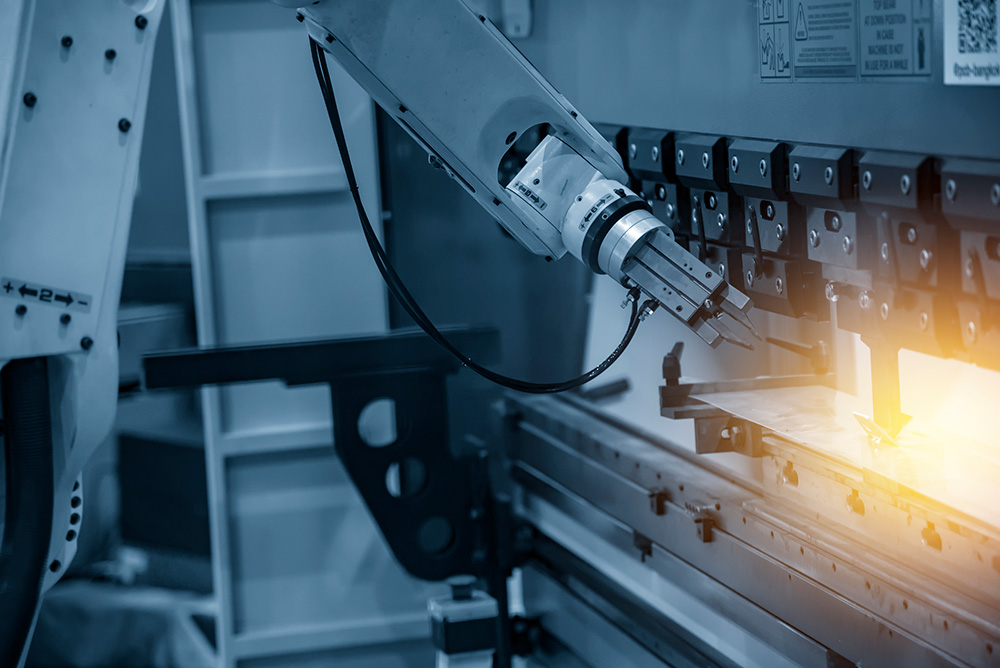

Improve Security

Improve Security Reduce Operational Issues

Reduce Operational Issues Lower the Cost

Lower the Cost Increase Productivity

Increase Productivity