-

Products

-

Solutions

-

Industry Solutions

-

Industry Solutions

-

-

Service Center

News

-

About Us

-

Investor

Join Us

Contact Us

Position MemoryPower-off memory for the mechanical zero position eliminates the need for frequent zeroing operations.

Position MemoryPower-off memory for the mechanical zero position eliminates the need for frequent zeroing operations.

Fast & Stable PositioningS-shaped motion curve planning to achieve stable and rapid rotary table positioning.

Fast & Stable PositioningS-shaped motion curve planning to achieve stable and rapid rotary table positioning.

Convenient & User-friendlyThe rotary table is simple to operate and convenient to control with selectable IO, AD, digital communication, and other control techniques for both forward and backward rotation.

Convenient & User-friendlyThe rotary table is simple to operate and convenient to control with selectable IO, AD, digital communication, and other control techniques for both forward and backward rotation.

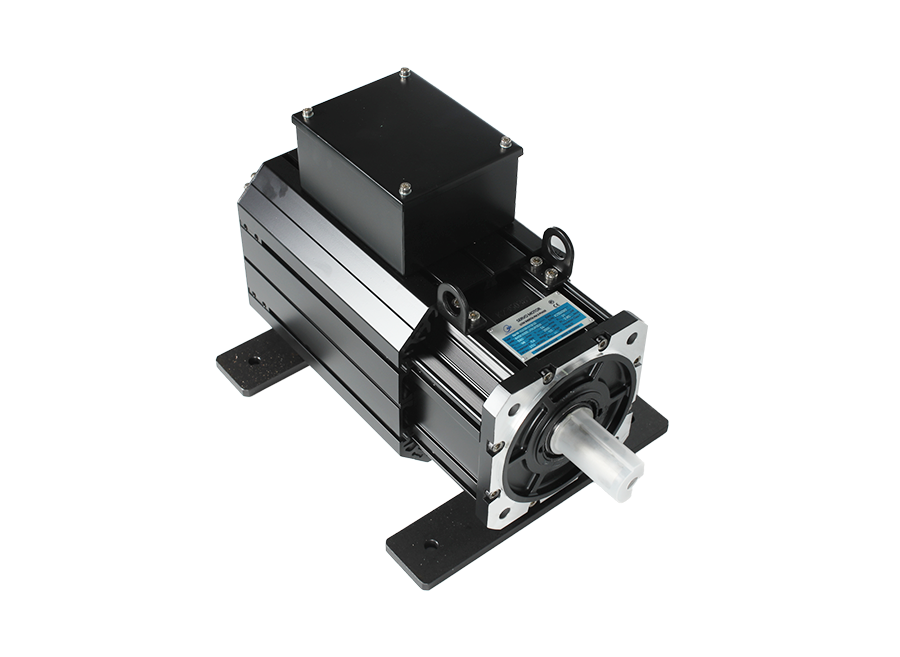

High Efficiency, Low Noise, Minimal BacklashUsing high-precision planetary reducers results in minimum backlash, low noise, and excellent efficiency.

High Efficiency, Low Noise, Minimal BacklashUsing high-precision planetary reducers results in minimum backlash, low noise, and excellent efficiency.

Multi-Turn Absolute EncoderThe use of 23-bit high-precision multi-turn absolute encoders considerably increases the positioning accuracy and repeatability of rotary tables.

Multi-Turn Absolute EncoderThe use of 23-bit high-precision multi-turn absolute encoders considerably increases the positioning accuracy and repeatability of rotary tables.

Multi-Station SetupSupports multi-station setups to satisfy a variety of process needs and allows for position adjustments to correct for machine inaccuracies.

Multi-Station SetupSupports multi-station setups to satisfy a variety of process needs and allows for position adjustments to correct for machine inaccuracies.

Minimize Machine DeteriorationSwitch to protective torque after achieving the desired position to reduce machine wear caused by excessive force.

Minimize Machine DeteriorationSwitch to protective torque after achieving the desired position to reduce machine wear caused by excessive force.