-

Products

-

Solutions

-

Industry Solutions

-

Industry Solutions

-

-

Service Center

News

-

About Us

-

Investor

Join Us

Contact Us

On April 20, 2023, CHINAPLAS 2023 was successfully concluded at the Shenzhen World Exhibition & Convention Center. The world fair lasted for four days, and the total number of visitors exceeded 240000 at a record high.

Techmation attended this world fair with the theme "Envisioning a Techmation Digital Vision" and achieved complete success!

Follow our camera and see what we have exhibited.

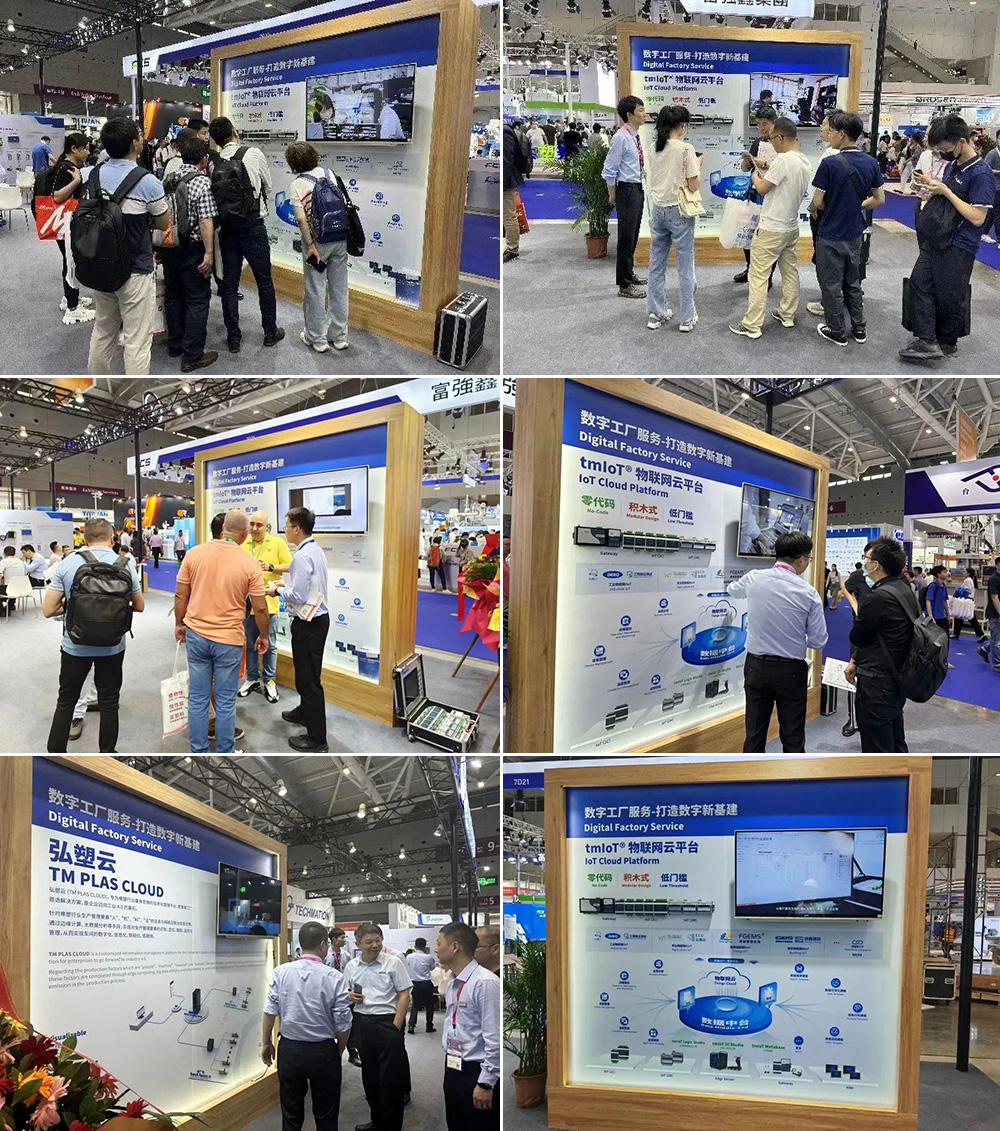

Eye-catching - Digital Solution

tmIoT® IoT Cloud Platform is a private cloud based on Nectar OS, an industrial operating system independently developed by Techmation.

With the design of no-code programming and IoT building-block programming, through the TMIoT database, standard components are configured like building with blocks. Through simple modular dragging with cloud tools, IoT applications can be easily achieved without any difficulty. It integrates with injection molding control systems and provides intelligent factory solutions through edge computing, big data analysis, and other means, making it the best choice for digital upgrading of the injection molding industry.

Brilliant-iTECH Series

Full Digital Control System Solution: iTECH Series, using our independently developed SA-BUS bus control, Full digital communication, simple wiring, and greatly improved real-time performance, stability, and expansibility bring more possibilities for injection molding control.

Dazzling-Rex Series

Open All Digital Solution: Rex Series, a processor hardware platform based on Cortex A53 architecture, and a new generation of electronic control systems that comply with PLCopen specifications. Adopting high-speed SA-BUS based on Ethernet with built-in motion control components named PLC SoftMotion, independently developed by us, is suitable for precise and high-speed industrial control of advanced equipment.

Impressive-SANDAL Series

All electric and hybrid control system solutions in the SANDAL series use our independently developed SA Communication System. Perfect integration with hardware such as our high-end plastic machine control system (SANDAL II), high-end robotic arm control system (THUJA), auxiliary equipment, etc. We offer a highly integrated "one machine with one manipulator" solution for plastic machine factories based on complete digital communication between the robotic arm and the injection molding machine, which is popular with many visitors.

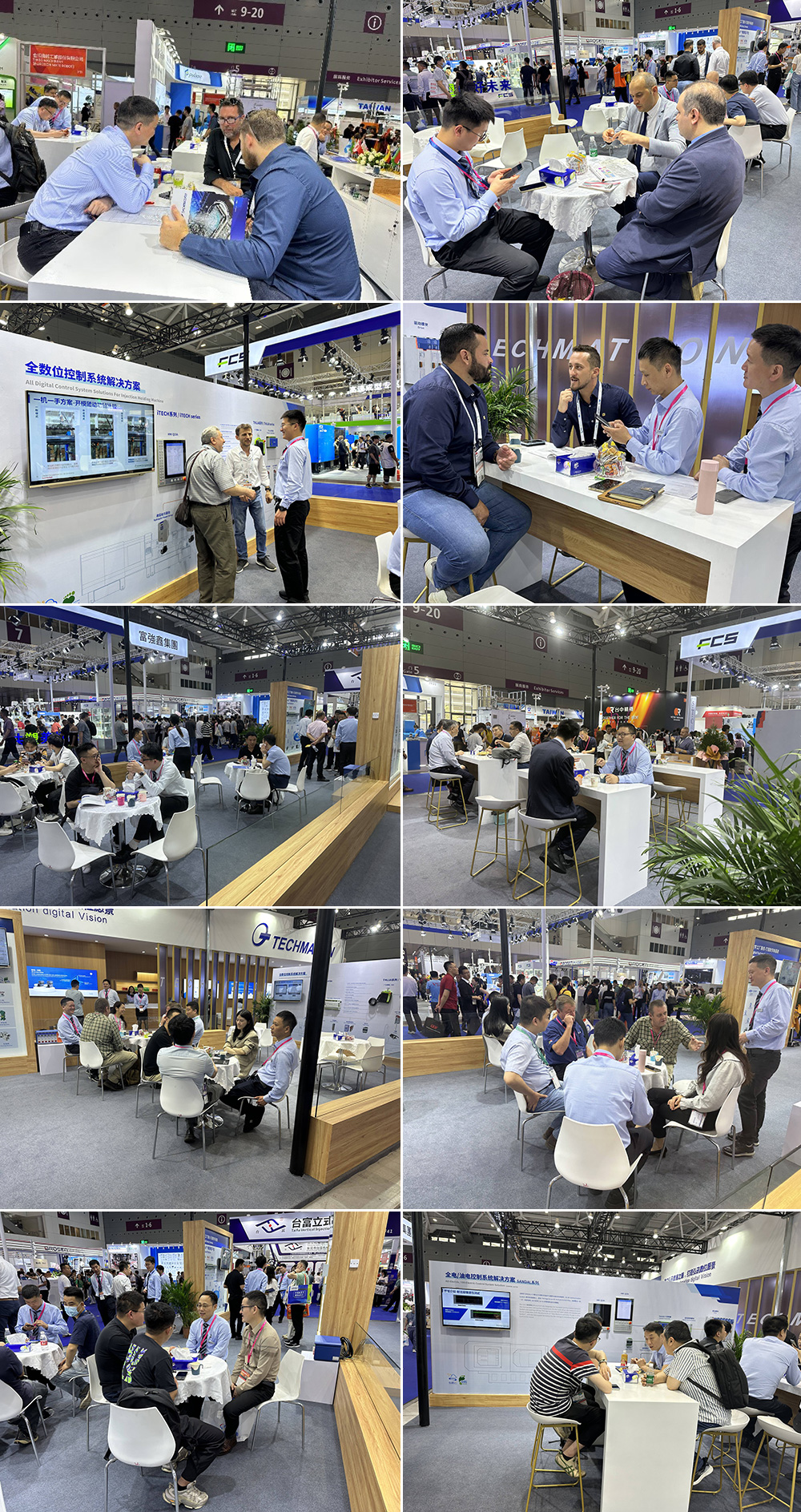

Chatting about cooperation, cherising friendship, and pursuing mutual growth.

We have been focusing on the automation field of the rubber and plastic industry for nearly 40 years, mastering industrial control technology, drive technology, communication bus technology, motion modules, control modules, manufacturing management, etc. Every breakthrough and progress we make is closely tied to the acknowledgement and support we receive from the industry and our customers..

Techmation will continue to carry out the mission of "leading industry development and promoting industrial upgrading," bringing more new concepts, products, and solutions to our customers, and writing a new chapter in the integration of intelligence and digitization of the plastic processing industry.

2024 @ Shanghai, see you there!