-

Products

-

Solutions

-

Industry Solutions

-

Industry Solutions

-

-

Service Center

News

-

About Us

-

Investor

Join Us

Contact Us

The 22nd China International Industry Fair 2020 was held at the National Exhibition and Convention Center (Shanghai) from September 15th to 19th. The metal industrial control systems of Techmation were showcased in whole.

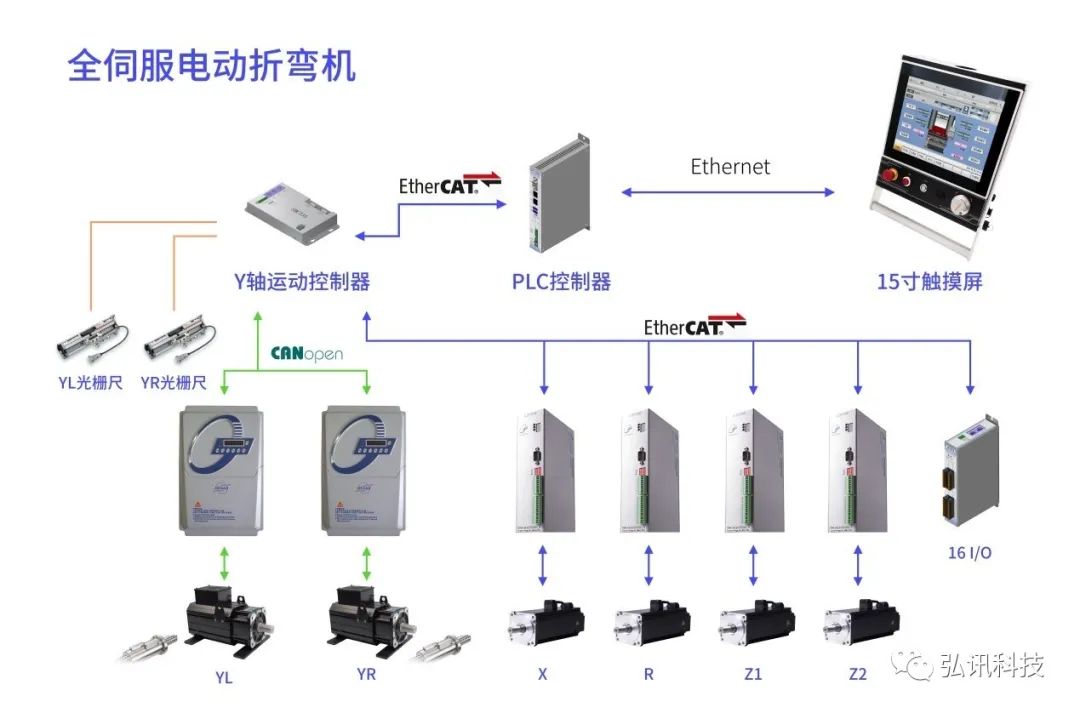

1. Fully Servo-Electric Bending Machine System

The system consists of many components, including a touch screen, drivers, servo motors, ball screws, and driving pulleys. The system enables control of 3-12 axes and incorporates high-capacity ball screws supplied from Japan, making it ideal for models up to 160T. The control system and driving unit use full digital communication, including EtherCAT communication or CAN communication bus, to ensure precise and stable management.

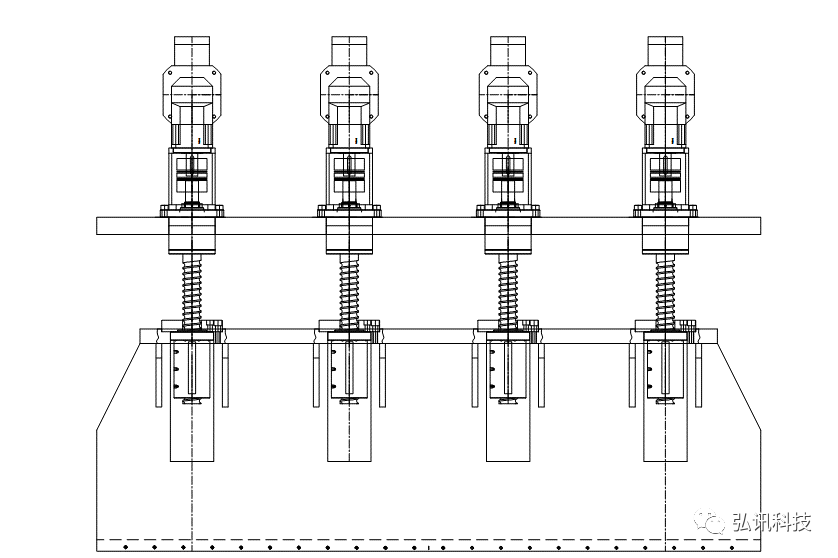

110-160T Four-Axis Synchronous Control:

The system uses sophisticated four-axis synchronous control technology along with specialized servo drives and motors. This arrangement ensures a more uniform distribution of force across the four Y axes, resulting in enhanced precision in bending and higher overall performance. Moreover, the ball screws are more cost-effective, providing a more economical alternative.

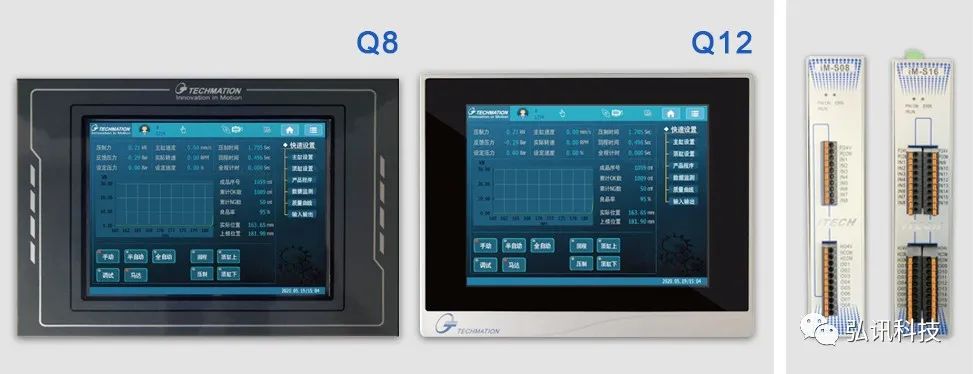

2. Solutions for Servo Hydraulic Press

The hydraulic press control system developed by Techmation uses its most recent HMI+TMPLC All in One architectural electrical control system, working together with its high-performance servo system. By applying TMPLC softmotion closed-loop control, precise regulation of constant pressure, constant stroke, and press-in displacement can be achieved. By virtue of the robust software capabilities, multiple peripheral interfaces, and incredibly fast response time, the hydraulic press can effortlessly accomplish the following:

Display and monitoring of force-displacement curves in real time

Online quality assessment that is diversified (window monitoring, monitoring point monitoring, and so forth).

Identify and regulate the implementation of force inflection points

Data tracing and OPC networking

Accuracy of positional repeatability: ±0.01mm

Oil pressure variation: ±5‰

Welcome to our booth 4.1 H-F150!