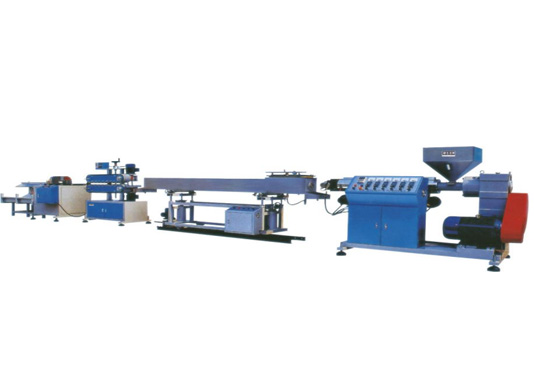

It is a machine that uses a scroll or plunger to extrude materials through a die head in order to create a product with a specific cross-sectional configuration.

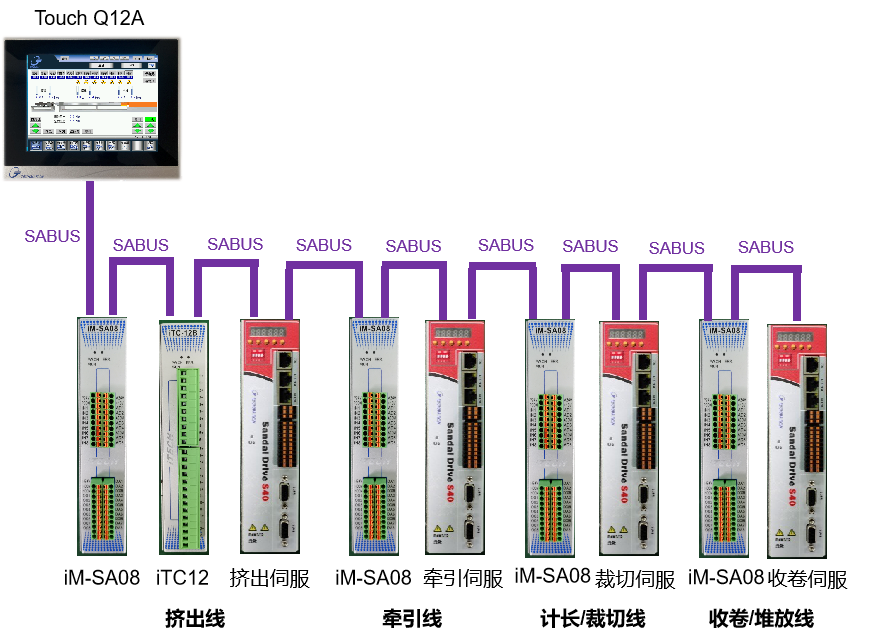

The system uses a dedicated electrical control system working together with a servo system to achieve closed-loop control over overall system speed, head pressure, and wall thickness. This ensures a high level of precision and responsiveness throughout the entire system. High-precision temperature control is achieved through centralized temperature control. This solution has been used on extruders, including sheet extruders, pipe extruders, sectional extruders, and granulators. By using a human-machine interface, touch screen, and frequency conversion technology, it achieves complete integration of intelligence and automation.

适用于各类型的挤出生产线

适用于各类型的挤出生产线 实现生产单元整合控制解决方案

实现生产单元整合控制解决方案 配合挤出机联网系统,实现生产车间联网管理

配合挤出机联网系统,实现生产车间联网管理 智能化控制,方便应用于调试,自动化程度高

智能化控制,方便应用于调试,自动化程度高 提供云服务,可远程协助、远程维护

提供云服务,可远程协助、远程维护