The solution created by Techmation satisfies the needs of molding machines that need to operate at a high rate of speed and responsiveness. In order to provide more consistent injection repeatability, it employs a 1GHz CPU with stable execution cycles and a new generation of its own hardware and software platform. Furthermore, the servo system with strong overload capacity and rapid response, coupled with a low-inertia embedded motor, meets the requirements of high injection speed and fast filling by virtue of fast speed response, capacity to exceed rated speed, and high overload capacity.

Application Field:The majority are thin-walled items, including fast food containers.

搭配比例方向阀的开模定位泵控算法,开关模周期≤2.3s,重复精度≤1mm,定位精度≤2mm。动作平稳,冲击小,有效延长机械寿命。

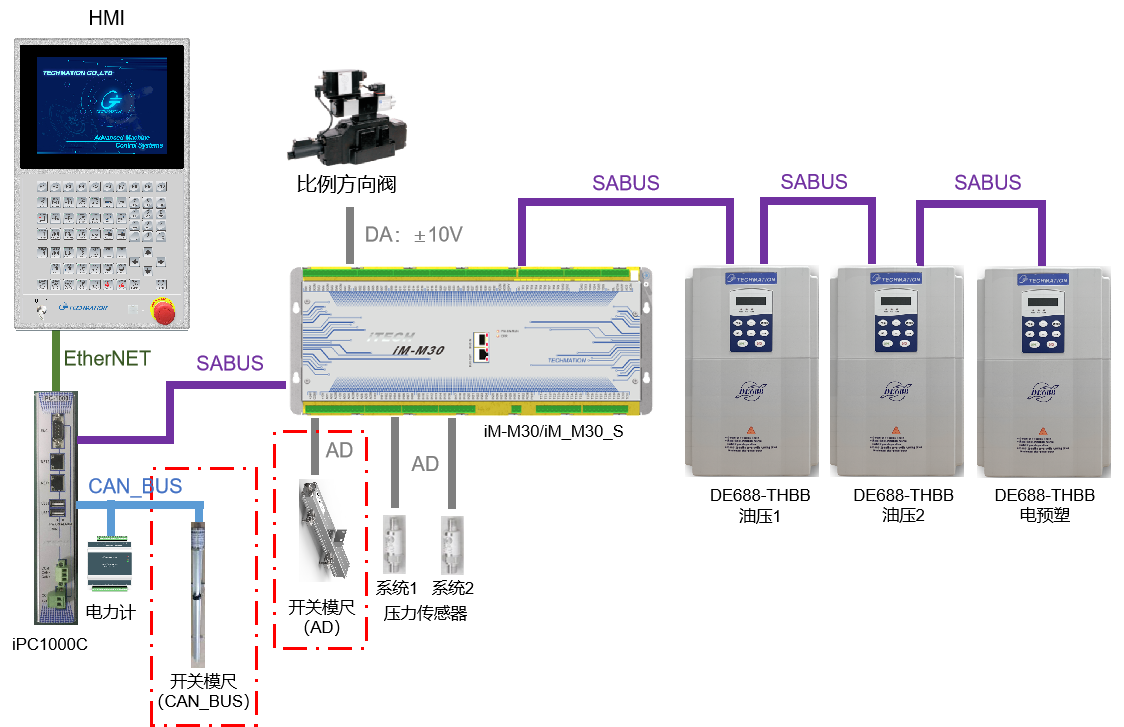

搭配比例方向阀的开模定位泵控算法,开关模周期≤2.3s,重复精度≤1mm,定位精度≤2mm。动作平稳,冲击小,有效延长机械寿命。 搭配高响应SABUS总线式伺服系统+低惯量内嵌式电机+高速高压系列油泵,电机加速响应时间≤34ms,射速加速响应时间≤39ms,射速加速响应距离≤14mm。

搭配高响应SABUS总线式伺服系统+低惯量内嵌式电机+高速高压系列油泵,电机加速响应时间≤34ms,射速加速响应时间≤39ms,射速加速响应距离≤14mm。 针对快速机塑化时间短,塑化要求高,搭配远红外加热圈等特点,优化温度PID控制算法,全自动生产过程中快速将温度稳定在设定值,温度波动≤1℃

针对快速机塑化时间短,塑化要求高,搭配远红外加热圈等特点,优化温度PID控制算法,全自动生产过程中快速将温度稳定在设定值,温度波动≤1℃ 采用自主研发的SABUS总线架构,通讯实时性更高,更稳定,扩展便利,接线简化。

采用自主研发的SABUS总线架构,通讯实时性更高,更稳定,扩展便利,接线简化。 多种方案搭配,满足客户节能需求,同时可实现各动作平稳,冲击小,减小油路冲击,降低油压部件漏油风险,有效延长机械寿命:

多种方案搭配,满足客户节能需求,同时可实现各动作平稳,冲击小,减小油路冲击,降低油压部件漏油风险,有效延长机械寿命: